The Facts Behind The Cost Of Grease

"Why is this so expensive?". "I’ll take the cheapest one you have." These are things we hear often, but just how important is the cost? Everyone understands the frustrations of finding the correct grease for the job at hand whilst doing their best to cut costs. Join us as we break down what makes up a grease, what bumps the price, and whether or not price matters.

Is All Grease The Same?

All grease consists of two main components - a base oil and thickener (then packed with several performance-enhancing additives). There are so many factors that change the characteristics of each grease, and we're exploring all of them.

Base oil - the foundations of lubricants. Three main types are synthetic, mineral and vegetable oils

Additives - added to improve performance and enhance qualities and features. These take up about 0.1% - 20% of the finished product. A few common additives would be:

- Rust & Corrosion Inhibitors - reduce or eliminate rust and corrosion by neutralising acids by forming a chemical barrier to repel moisture

- Antioxidants - extends life and are present in almost every oil or grease. They delay oxidation and protect the base oil

- Anti-Wear (AW) Additives - activated by the heat of contact, forming a protective film against wear

- Extreme Pressure (EP) Additives - activated at high loads and pressure to form a protective film/barrier against wearing surfaces

- Viscosity Index Improvers - polymer additives that help reduce the process of thinning as the temperature increases

- Detergents - used alongside a dispersant additive, neutralising the acids in oil as well as keeping hot metal components clean and deposit free

- Dispersant - the alliance of detergent and dispersant additives, acids neutralise and contaminants are suspended.

- Emulsifiers - helps bind oil and water together, creating a stable oil-water emulsion. Used in oil-water-based metal-working solutions as well as fire-resistant fluids

Viscosity - The viscosity dictates the stability and resistance to friction within extreme environments. High viscosity is suitable for high-speed environments and low viscosity is more suited to slow and/or heavy loads.

Thickener- increases the efficiency of grease by helping grease components bond. These influence the overall consistency

Consistency - determines the level of softness/hardness of every grease. Defined by NGLI, each grease has a number to express the level of consistency.

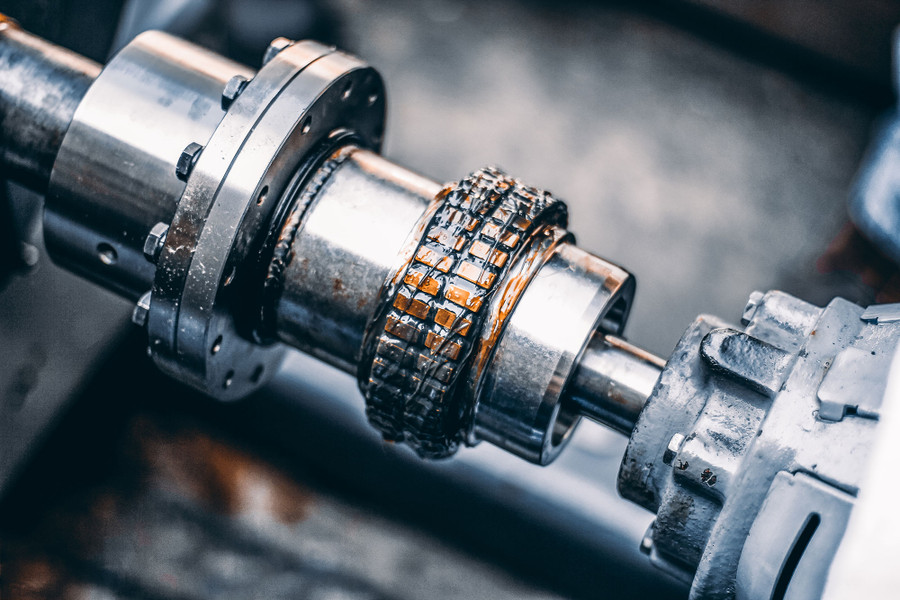

How Do Machine Factors Impact Price?

You can see the number of variables a grease has, all of which influence performance. So, does this mean more expensive is better? Hard to answer with a yes or no! There are so many machine factors to consider that all make a difference to the price.

For instance: running temperature, exposures, humidity, slow loads, friction, even machine type. Many of you are more conscious and are pressured to reduce the costs of lubrication and processes but some don’t consider the high cost when settling for a cheap, low-grade grease.

Can The Application Process Make A Difference?

The price charged may be appealing, however, the impact of incorrect lubrication defeats the purpose of going for the cheap option. In most cases, the more expensive greases are, the more likely they are to have a better success rate in performance. This is mainly down to the additive package.

When it comes to grease with a higher price point, you can expect the likes of recommended ratings on viscosity, excellent water and dirt repulsion and high melting points. All of these improve the performance of the grease, and your application.

It is so important to consider the lubrication process, and if this is being implemented properly.

No matter how high the cost, if the grease isn't applied correctly there's no justifying the price. At TYGRIS, we identify where areas need better lubrication, and recommend the best-suited option in your environments.

Our free technical visits are available, helping you highlight issues and giving you confidence as to which product we know you need - fixing long term pains with products we know solve issues. We avoid taking a ‘band-aid approach’ with our solutions. Our team has years of experience, and have come up with innovative products to fix problems.

Here at TYGRIS, we tend not to focus on price. It is the last thing we discuss! Far outweighing the inconvenience and impacts of incorrect use of grease and processes.