TYGRIS Academy

Welcome to TYGRIS Academy! Gear up and and get ready to learn about all things lubrication, protection, cleaning and more...

Most Recent Posts

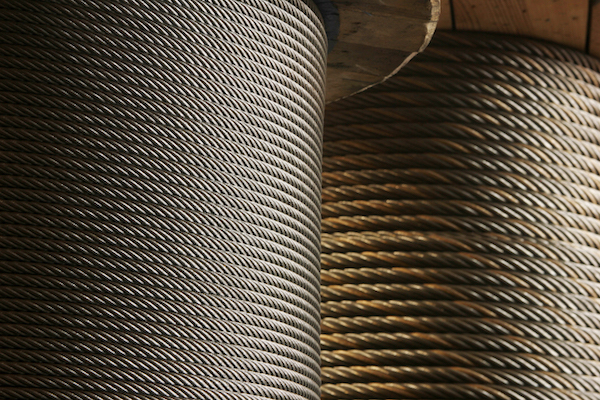

Our Top Wire Rope Lubrication Methods

The Step-By-Step Guide To Finding The Grease You Need

What Are Auto Greasers And Why Should You Use Them

The Step-By-Step Guide To Finding The Grease You Need

What Are Auto Greasers And Why Should You Use Them

TYGRIS Tips

Has your machinery hit a road block? Are you looking for quick tips and support to help make the most of your machinery and optimise your operations? TYGRIS Top Tips has got you covered with guides, methods and processes YOU can use to boost your business.

Industrial Solutions

Looking to find out more about some of our latest industrial innovations? Keep reading to find out how our lubricants, cleaners and protective kits can help YOU reduce downtime and increase efficiency.

Grease

Grease 101: Find out more about the many uses, functions, and solutions that our ranges of TYGRIS Greases provide many business across all sectors, to help them optimise their lubrication processes and refine their mechanical operations.